In the context of Industry 4.0, labor shortages, and the need for resilient supply chains, the implementation of Automated Guided Vehicles (AGVs) in factories is not just a trend but a key factor for sustainable business development. Phenikaa-X will help you delve deeper into Factory AGV, exploring their 06 core benefits, 05 common types are being used widely, and real-world success stories to highlight their immense potential.

1. What Is a Factory AGV?

A Factory AGV (Automated Guided Vehicle) is a system of self-navigating vehicles programmed to transport materials within factory and warehouse environments along fixed routes, enhancing efficiency and workplace safety.

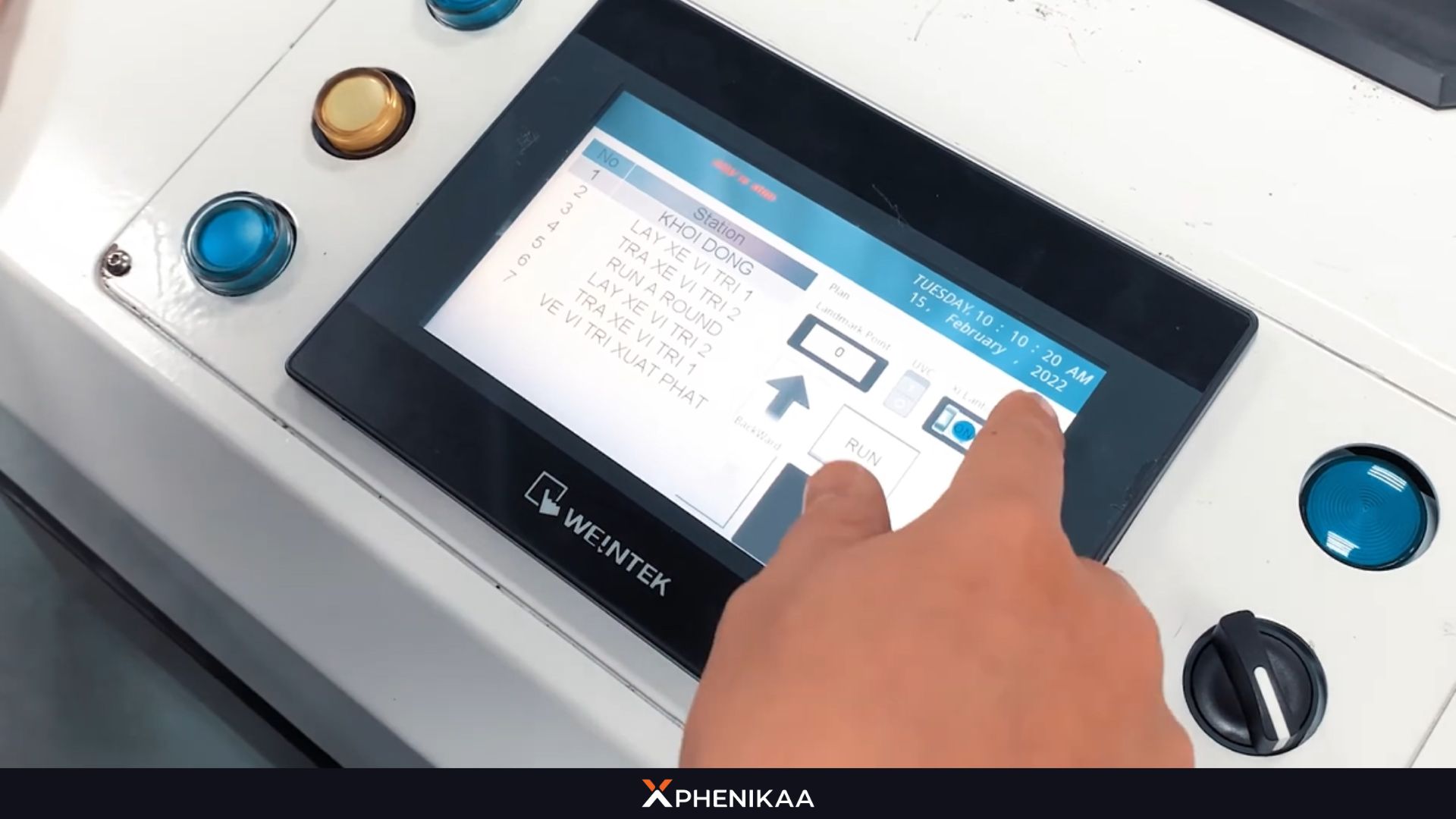

Factory AGVs are a type of AGV (Automated Guided Vehicle) designed to autonomously transport goods, raw materials, or semi-finished products inside a manufacturing facility without direct human intervention. These AGVs move along pre-defined paths, typically guided by laser, magnetic tape, optical sensors, or advanced LiDAR and navigation systems.

The payload capacity of AGVs varies widely, from a few dozen kilograms to tens of tons, depending on their design and intended use. The speed of AGVs is also flexibly adjusted to ensure optimal safety and efficiency within the production environment.

While Factory AGVs operate along fixed paths, a newer generation of robots, AMRs (Autonomous Mobile Robots), offers more flexible navigation capabilities thanks to artificial intelligence and complex sensors.

| Feature | AGV | AMR |

| Navigation | Fixed paths (e.g., tape/laser) | Dynamic (AI + sensors, SLAM) |

| Flexibility | Medium (structured routes) | High (adapts to changes) |

| Upfront Cost | Lower (~$10K–$100K) | Higher (~$20K–$150K) |

This fundamental difference shapes their applications: Factory AGVs are suitable for repetitive tasks on known routes, while AMRs are ideal for dynamic environments requiring complex navigation. Both play a crucial role in modern AGV factory systems.

You can find out more about in depth comparison of AGV with AMR in this article:

>>> AGV vs AMR – Key Differences Comparison

2. 06 Key Benefits of Factory AGV in Manufacturing

Investing in a Factory AGV is not just an expense but a strategic investment that brings immense value to businesses. Here are the 06 most significant benefits of Factory AGVs in manufacturing that Phenikaa-X wants to highlight:

2.1. Factory AGV Can Boost Operational Efficiency

AGV have the capability to work non-stop, 24 hours a day, 7 days a week, completely eliminating downtime due to human breaks, shifts, or fatigue. This ensures a continuous flow of materials, minimizes production bottlenecks, and accelerates the product completion cycle.

For example, an automotive manufacturing plant increased its assembly line throughput by 20% in just six months after implementing an AGV system, significantly reducing waiting times between stages. This is one of the most evident AGV benefits in manufacturing.

2.2. Factory AGV Address Labor Shortages and Reduce Costs

With manufacturing labor shortages projected to worsen in 2025 – exacerbated by an aging workforce and skill gaps – factory AGVs automate repetitive, heavy-lifting tasks, reallocating human workers to value-added roles like oversight and innovation.

This could be the solution to labor shortages in certain specialized manufacturing sectors. Examples include chemical processing plants, raw material handling facilities, and heavy metal fabrication factories – industries that are critical to the economy but chronically understaffed due to unsafe working conditions or high skill requirements.

2.3. Improving Workplace Safety

Safety is always a top priority in a factory environment. Manual forklifts and transport equipment are often major causes of serious workplace accidents. Factory AGVs are equipped with multiple safety sensors, emergency stop systems, and obstacle detection capabilities, allowing them to move precisely and safely. Eliminating direct human interaction in dangerous transport tasks significantly reduces the number of accidents, injuries, and property damage.

OSHA studies indicate that automated systems like AGVs can cut transport-related injuries by up to 70%, lowering claims and downtime. In dynamic 2025 environments, their precision navigation further minimizes risks, fostering safer, more compliant operations.

2.4. Factory AGV Help Minimize Product Damage and Waste

Manual material handling always carries the risk of product damage due to human error, collisions, or drops. Factory AGV, with their precise movements and meticulously programmed paths, minimize these risks. They transport goods gently and stably, ensuring product quality from the beginning to the end of the production chain.

2.5. How Does Factory AGV Scale Seamlessly with Production Demand?

One of the major advantages of Factory AGVs is their flexible scalability. When production demand increases, businesses can easily add more AGVs to their existing fleet without major infrastructure changes. Conversely, when demand decreases, some AGVs can be temporarily idled to save costs. This helps factories quickly adapt to market fluctuations, optimize capacity, and avoid wasted investment. This capability is especially crucial in today’s dynamic business environment.

2.6. How Does Factory AGV Integrate with IoT and WMS for Smart Factories?

One of the key considerations for businesses when implementing factory AGV systems is their compatibility with existing smart factory infrastructure. These AGVs seamlessly integrate with IoT platforms to transmit real-time data on location, battery levels, and operational performance. They also connect directly with Warehouse Management Systems (WMS) and Manufacturing Execution Systems (MES) to receive transport orders, confirm task completion, and dynamically reroute as needed.

This interoperability ensures a unified flow of data and materials, enabling maximum operational efficiency, informed decision-making, and full-scale automation—making integration a cornerstone of modern smart factory AGV solutions.

You can learn more about this topic in the AGV software article, shared by Phenikaa-X’s engineers.

3. What Are 5 Common Types of Factory AGV Used in Modern Plants?

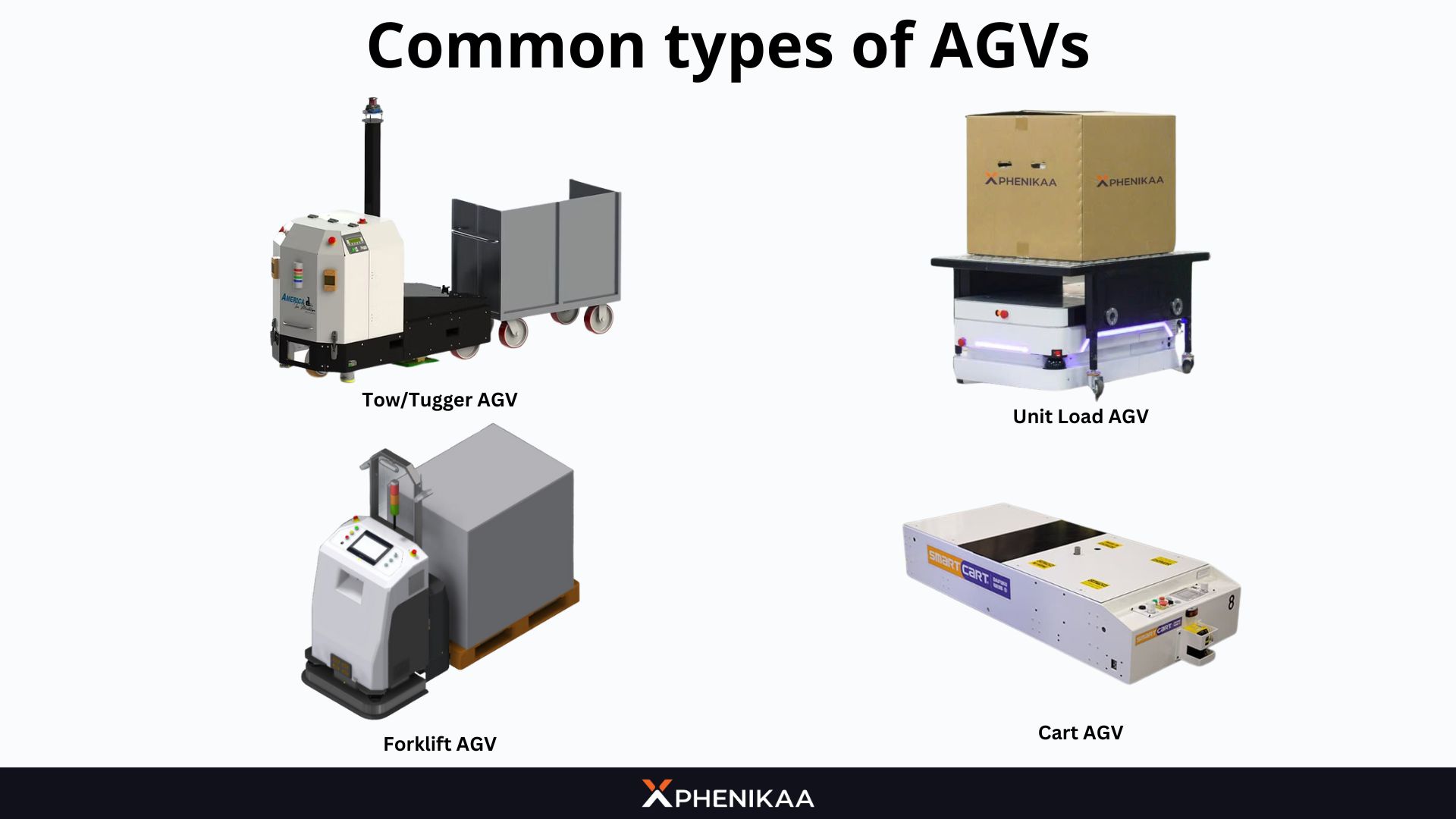

To meet the diverse transportation needs within factory environments, various industrial factory AGV types are available. Choosing the right AGV type will optimize efficiency and investment costs. Here are 5 common types of AGVs:

- Forklift AGV: Designed to autonomously lift and move pallets and large containers. They can operate in high-rack warehouses and crowded environments. Typical specifications: 1–10 ton lifting capacity, up to 6 meter lift height, 1–1.5 m/s speed.

- Towing/Tugger AGV: Specialized for towing multiple carts or trailers containing materials. Often used to supply components to assembly lines. Typical specifications: 500 kg – several tons towing capacity, ability to connect multiple trailers in train formation.

- Unit Load AGV: Transport standardized unit loads such as boxes, bins, or single pallets. They often have lift tables or rollers for easy material transfer. Typical specifications: 100 kg – 3 ton load capacity, can integrate with conveyors.

- Heavy Load AGV: Used for transporting super heavy materials, from 1 ton to over 50 tons, such as large steel coils, industrial molds, or bulky machinery parts. Typical specifications: load capacity 1+ ton as standard, robust chassis design for harsh environments.

- Automated Guided Carts (AGC): Compact and efficient for moving small to medium loads over short distances. Ideal for repetitive tasks in assembly and warehousing. Typical specifications: 200 kg – 2 ton load capacity, simple flat deck design, easy integration with existing workflows.

4. Factory AGV in Action: What Are 3 Real-World Success Stories?

To better visualize the impact of Factory AGVs, let’s look at some prominent AGV implementation in industry cases Phenikaa-X wants to highlight:

- Ford (Michigan, USA):

With over 120 AGVs deployed, Ford increased its assembly line throughput by up to 30%, enabling faster and more efficient production of new vehicle models. - Amazon (Fulfillment Centers):

The use of thousands of AGVs has helped Amazon reduce intra-logistics costs by 25%, optimizing picking and packing processes, and significantly speeding up delivery times. - Siemens (Germany):

Siemens’ AGV fleet at its electronics assembly plant achieved 99.9% uptime, ensuring no disruptions in the supply chain of critical components, a testament to AGV reliability.

Conclusion

Factory AGVs are no longer a luxury technology but have become an essential solution for factories seeking competitiveness and sustainability in 2025 and beyond. From boosting efficiency and reducing costs to improving safety and scalability, AGVs offer comprehensive benefits, meeting the demanding requirements of modern manufacturing.

Are you ready to automate your manufacturing processes with advanced Factory AGV solutions? Contact Phenikaa-X experts today for consultation and to learn more about how AGVs can transform your factory at:

- Facebook: https://www.facebook.com/phenikaa.x

- Hotline: (+84) 904530545

- Email: contact@phenikaa-x.com