AMR robots is a robust technology often come with different types, fulfill all the needs from various fields, from sorting items, carrying products and many other applications. So how many AMR types are there and which is the most common? Phenikaa-X will guide you through this question in this article and learn all about different types of AMRs.

1. Common Types of AMRs

Autonomous Mobile Robots (AMR) are advanced robotic systems capable of transforming industries by enhancing efficiency and flexibility, making them vital for multiple fields of industry thanks to the variety of AMR types. Understanding the diverse AMR types is crucial for selecting the right solution for specific operational needs. Below, Phenikaa-X will provide you with a category of AMR types, sorted by the purpose of use on each of them.

1.1. AMRs for Moving Inventory Within a Facility

AMRs for moving inside facility are designed to transport inventory, such as boxes, pallets, or SKUs, within a facility, streamlining material flow. They handle diverse tasks, from moving goods between storage and production to towing carts, reducing manual labor and enhancing efficiency.

These AMRs vary in size and structure, from compact platforms to heavy-duty frames, with payloads ranging from 100 to 2,500 kg. They feature flatbeds, forks or towing mechanisms, equipped with SLAM, dual LiDAR and robust wheels for navigation across varied surfaces in busy environments. These benefits make AMR in Warehouse be the first pick among all, allowing management in this field to operate autonomously.

Predominantly used in warehousing and manufacturing, these AMRs support industries like automotive, electronics, and consumer goods by optimizing internal logistics and minimizing downtime.

- Platform AMR: Compact flatbed robots, designed for light to medium loads (100–600 kg), ideal for transporting small parts or SKUs in tight spaces.

- Manual Loading AMR: This model is built for manual loading of heavy items up to 1,500 kg, suited for large-scale manufacturing with flexible payload handling.

- Forklifting AMR: Equipped with forks for pallet handling and high-lift tasks up to 10 meters, perfect for stacking and racking in warehouses.

- Cart Pulling AMR: This AMR equipped with a cart attachment part, designed to pull carts with pallets or inventory up to 2,000 kg, optimizing bulk transport in distribution centers.

- Heavy Load AMR: Robust models for oversized or heavy inventory up to 2,500 kg, featuring reinforced frames for demanding manufacturing environments.

- Tugger AMR: Specialized for towing multiple carts in a train-like configuration, enhancing bulk transport efficiency in large facilities.

Their average pricing ranges from $15,000 to $100,000 per unit, depending on payload capacity, lifting or towing capabilities, and integration complexity.

1.2. AMRs for Assisting in the Picking Process

Picking Assistance AMR is a type of AMR used to collaborate with workers, carrying bins and following them during order picking to enhance efficiency. They reduce physical strain and improve accuracy in repetitive tasks.

These AMRs are lightweight and slim, featuring integrated robotic arms or bins for picking up products or components. Some modern types are also equipped with AI-driven vision systems for real-time interaction and picking guidance, ensuring high accuracy of shorting products.

This AMR type is most used in distribution centers and retail, Picking Assistance AMRs boost productivity in order fulfillment for companies like Walmart and Zara. With the costs range from $25,000 to $60,000 per unit, they are considered a cheap and easy to install option for autonomous operation.

- Mobile Picking AMR: AMR equipped with modular trays for goods-to-person picking, designed to navigate under shelves and deliver items to workers.

- Conveyor AMR: Conveyor-like surfaces for transporting picked items to packing stations, allowing them enhancing workflow efficiency in dynamic picking environments.

1.3. AMR for Flexible Sortation Solutions

AMR for Flexible Sortation Solutions are designed to automate the sorting of items by size, weight, or destination, handling diverse inventory in high-volume operations. They streamline parcel sorting and order consolidation, reducing processing times in logistics-heavy environments. Cobot Arm AMR is the variant used for this task, thanks to a robotic arm or tilt-tray mechanism for high-speed parcel sorting, adaptable to mixed-SKU environments with precise item handling.

To ensure the AMR provides the most support for its role, AMR in this category often features conveyor tops, tilt trays, or robotic arms for sorting. Some variants are also have barcode scanners, weight sensors and advanced software for precise item routing, with modular designs for compatibility with existing systems.

At the moment, they are most commonly used in e-commerce, postal services and logistics. Companies like FedEx, DHL and Alibaba have already used them in sorting parcels and optimizing order processing. The price is around $25,000 to $50,000 per unit installed, depending on sorting speed, sensor sophistication and other features

1.4. Service AMR

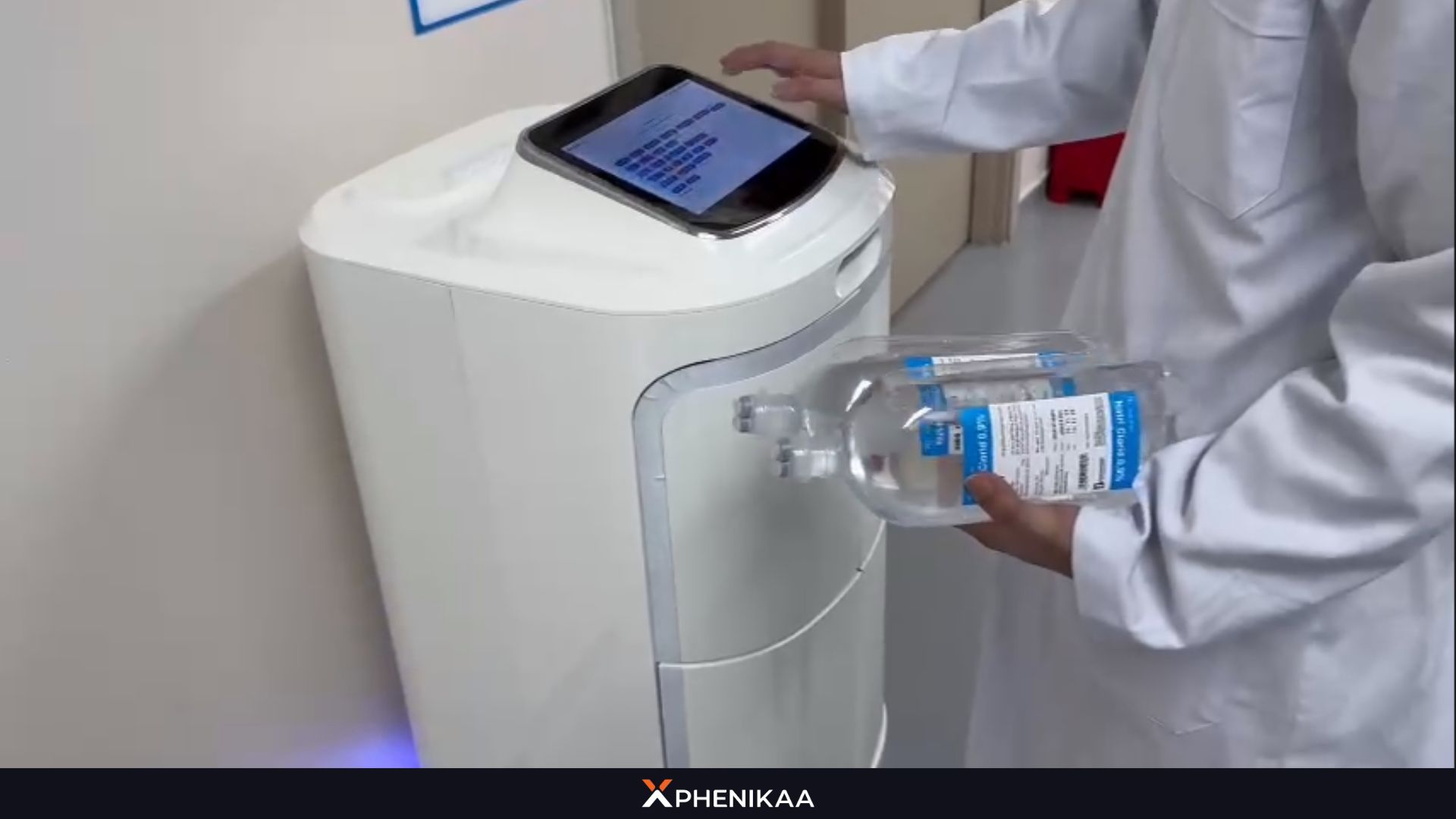

Service AMR is the most known type of AMR nowaday, also called “service bots” on social media, thanks to the internet. They are designed for non-industrial tasks, oftenly small and agile, allowing them to work perfectly inside buildings like hospitals, hotels and restaurants.

This type of AMR features storage or trays to deliver services (food, drinks and other lightweight stuff). Depending on the field of work, they are also equipped with specialized components, such as UV lamps or insulated trays for the hospital’s support variant. Some manufacturers even gave them humanoid designs, including user-friendly interfaces and AI technology to further boost their services. This feature is also the cause of them being viral on the internet.

Normally, the price of these robots is around between $10,000 and $30,000 per unit, depending on specialized features. This is considered a fairly cheap price to import automation tech to your service business, which makes them being tested in multiple different tourism brands and hospitals around the world.

2. Choosing the Right AMR Type for Your Business

Selecting the appropriate Type of AMR requires careful consideration of operational needs and constraints. Below are key factors to guide your decision, along with insights into the most common AMR type and the benefits of a mixed fleet.

Considerations for Selection

There are multiple things that need to be considered before the investment of the AMR. Normally, Phenikaa-X’s salesman offers our business partner the correct type of AMR to be looking for:

- Facility Layout: Depending on how big your operation and facility is, we offer different types of AMR. Narrow aisles favor compact size AMR for Assisting in the Picking Process, while large warehouses benefit from AMR for Moving Inventory with high payload or towing capacities.

- Task Requirements: AMR are capable of carrying weight between 150kg (compact AMR) to 2.5 tons (Heavy lifting AMR). Also, they are able to equip with different types of add-on for different uses: lifting or cart towing requires AMRs for Moving Inventory, such as Forklifting or Tugger AMRs, whereas sorting tasks demand Flexible Sortation Solutions.

- Scalability: AMRs for Moving Inventory, like Platform or Heavy Load AMRs, support expanding operations with versatile payload options.

- Budget: AMRs for Assisting in the Picking Process offer cost-effective solutions starting at $20,000, while heavy-duty inventory AMRs may exceed $100,000.

Most Common Type of AMR

Delivery AMR is the most common Type of AMR at the moment, particularly in e-commerce and logistics. Their compact design, affordability (starting at $20,000), and ability to reduce picking times by up to 50% make them a go-to choice for businesses optimizing warehouse operations. Companies like Amazon rely heavily on AMR fleet to meet rapid delivery expectations, highlighting their dominance in the market.

Some data showed that Service AMR is also in trend thanks to social media, especially humanoid types. This AMR often appears in the service field, like in restaurants, resorts or hospitals, providing not just their service but also emotional satisfaction to the customer. Not only children but also adults are attracted to them, making them highly potential in the future.

Should You Use Different Types of AMR?

Deploying multiple AMR types can significantly enhance operational efficiency. For example, combining delivery AMR for carry products with Autonomous Forklifts for heavy lifting creates a versatile workflow, addressing diverse tasks within a single facility. A mixed fleet improves scalability and adaptability, allowing businesses to respond to changing demands.

However, challenges such as integration complexity and maintenance costs should be considered. Please dont be hesitated to consulting your problems and needs with Phenikaa-X for a custom design of AMR that meet your business strategy.

Understanding how Autonomous Mobile Robots work is crucial before investing in this breakthrough technology. Phenikaa-X’s article, shared by our head engineer, will help you gain a deep understanding of how AMRs function and how they can enhance your production processes.

Conclusion

AMR types are reshaping industries by offering tailored automation solutions for diverse needs. From Goods-to-Person AMRs driving e-commerce efficiency to Autonomous Forklifts handling heavy loads in manufacturing, each Type of AMR brings unique capabilities. Service and Delivery AMRs enhance healthcare and hospitality, while Inventory Transport and Picking Assistance AMRs optimize logistics and retail. By understanding these AMR types, businesses can select the right solutions to boost productivity and scalability.

Phenikaa X is one of the best AGV and robotic solutions providers. Contact us today to learn more about integrating AMRs into your business:

- Facebook: https://www.facebook.com/phenikaa.x

- Hotline: (+84) 904530545

- Email: contact@phenikaa-x.com