In modern industrial warehouse sectors, warehouse robots have become an indispensable component, completely changing how warehouses and factories function and enabling businesses to gradually adopt automated warehouse models. This makes understanding these technologies increasingly critical for enterprises and warehouse managers to implement efficient and cost-effective automation. So what makes them become special and important in modern industry? Let’s find out together with Phenikaa-X in this article.

1. Introduction to Warehouse Robots

What Are Warehouse Robots?

Warehouse robots are automated robots designed to replace or support humans performing tasks such as picking, packing, transporting and inventory management inside warehouses and distribution centers. The purpose of these robots is to enhance efficiency and accuracy in logistics, enabling seamless operations in dynamic environments.

Imagine a warehouse where robots zoom through aisles, grab items, move pallets – cargo – packages and track inventory – all without a break. That’s warehouse robots in action. They’re the heart of warehouse automation robotics, turning slow manual processes into fast, smart operations, while at the same time, providing safety inside the facility.

Advanced tech like artificial intelligence (AI), machine learning, sensors and Internet of Things (IoT) powers their autonomy. In an automated warehouse, robots navigate complex layouts, dodge obstacles and deliver items to workers. This helps workers cut time spent on repetitive tasks, boost efficiency.

Why is Robotics in Warehouse Matter 2025?

As the e-commerce market continues to expand, becoming a key sector globally, warehouses and factories frequently face overload due to labor shortages and high labor costs. Warehouse robots have emerged as an effective solution, offering low costs, high productivity, and ease of use.

Particularly, technological advancements in recent years (from 2020 to 2025), including AI 4.0, IoT and navigation technologies (SLAM and LiDAR), have become increasingly sophisticated. This has made robots in warehouses more advanced and accessible. Commonly used modern robots, such as AGVs, AMRs and conveyor robots, significantly enhance warehouse robotics solutions for efficient inventory and logistics management. From startups to global giants, robots are reshaping logistics for all scales at recognizable speed.

2. Tasks Warehouse Robots Can Replace or Support

Below, Phenikaa-X highlights key tasks where warehouse robots excel, helping businesses optimize operations:

- Picking and Packing: Robots with automated arms can perform picking and placing tasks up-and-down from shelves, or packing them for shipment, reducing human effort in repetitive tasks.

- Inventory Management: Robots equipped with RFID scanners can track inventory in real-time, replacing manual stock checks by regular labors. This increases accurate stock levels and reduces staff time.

- Material Transport: These robots can easily handle heavy lifting, moving pallets or goods across warehouses without human intervention.

- Sorting and Order Fulfillment: Categorize items automatically by size, weight, or destination, speeding up order processing for logistics automation robotics.

These tasks, once labor-intensive, are now optimized by warehouse robots, enabling businesses to address labor shortages and scale operations efficiently while maintaining high safety and accuracy standards.

3. Benefits of Warehouse Robots

The upside from having these warehouse robots is vary, including cost savings and safer workplaces, which are 02 main concerns by many business owners. Here’s the rundown, provided by Phenikaa-X’s researcher:

3.1 Boosted Efficiency and Productivity

Warehouse robots are capable of working 24/7, no breaks needed. This allows them to increase productivity by 30–50% compared to just human work alone. They speed up goods-to-person robots and automated pallet movers, cutting idle time.

Several warehouses worldwide have experimented with “unmanned” models to reduce labor costs while enabling fully automated operations. A prime example is the No-Light Factory in China, one of the first warehouses globally to operate entirely with robots, requiring no human presence or lighting.

Learn more about No-Light Factory and others automation facilities in 03 AMR Implementation Case Studies in China, researched and shared by Phenikaa-X’s Market researcher.

3.2 Safer Work Environments

A warehouse work environment can be hazardous with heavy loads and crowded aisles, making risk of injury always exist. Robots in warehouses handle risky tasks, reducing injuries by up to 25%, based on research of HSI (Health and Safety International). They meet safety standards like OSHA, ensuring safe human-robot teamwork in fulfillment robots and robotics in warehouse management.

Some types of modern autonomous robots are equipped with advanced sensor technologies like SLAM and LiDAR. These technologies enable robots to detect obstacles, including humans, on their paths and calculate avoidance routes, minimizing accidents and collisions in warehouses while ensuring the safety of the workforce.

3.3 Big Cost Savings

By automating repetitive tasks, warehouse robots cut labor costs, with ROI often achieved in 1–2 years, based on the feedback of Phenikaa-X’s customers. Fewer errors and predictive maintenance reduce waste and downtime in warehouse robotics automation. Energy-efficient designs in transport robots further lower costs, making automation affordable for all business sizes.

3.4 Scalability and Flexibility

Warehouse robots scale effortlessly for demand spikes, like holiday rushes, thanks to modular designs in automated warehousing systems. They support hybrid human-robot setups, adapting to changing needs without major overhauls, keeping robotics in warehouse management agile.

3.5 Extra Strategic Wins

In terms of working efficiency, robots in warehouses can offer accuracy in inventory and order fulfillment, reducing errors and fueling data-driven decisions in benefits of warehouse robotics. They also cut emissions with optimized energy use, aligning with 2025’s green trends. IoT integration streamlines operations, making autonomous warehouse robots a powerhouse for innovation.

4. Types of Warehouse Robotics

Each type of warehouse robot brings unique strengths to automated warehouse systems, addressing specific operational needs from navigation to precision handling. In 2025, advancements are blending categories, creating versatile solutions for modern logistics.

Below, Phenikaa-X listed 05 most common types of robots in warehouse based on their operational principles, technical capabilities and critical roles in logistics automation robotics.

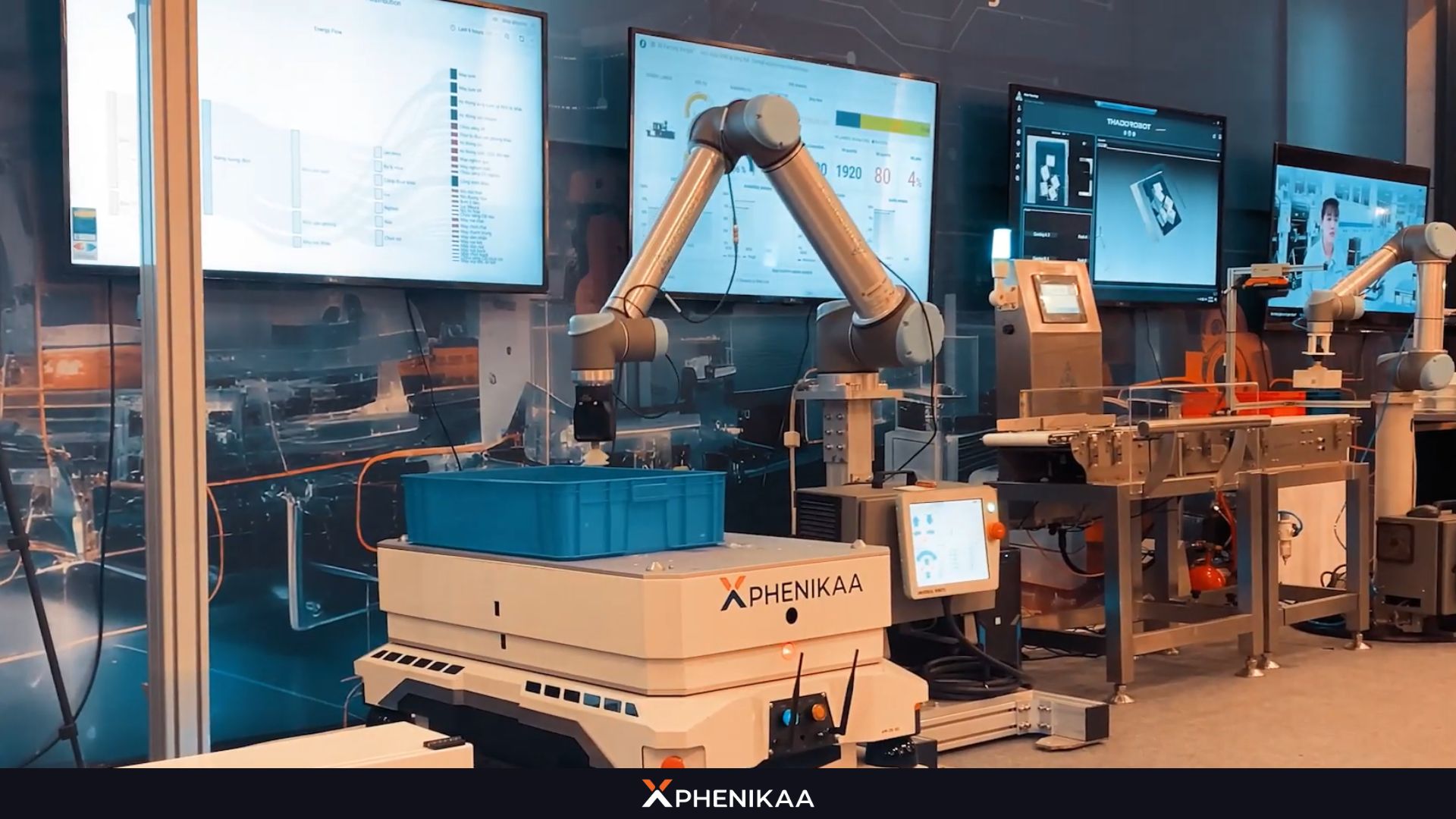

4.1 Autonomous Mobile Robots – AMR

Autonomous Mobile Robots (AMR) are currently the most modern type of automation in warehouses. They are designed to navigate freely without reliance on fixed paths or infrastructure. Unlike traditional robots, AMR leverages advanced technologies like LiDAR, SLAM to build real-time 3D maps of their surroundings and some are even with AI and IoT to enhance their capability. This enables them to dynamically adjust routes, avoid obstacles such as workers or misplaced inventory, and operate in ever-changing warehouse layouts in the most efficient way.

In warehousing, they are tasked with picking, transporting and restocking products, which are common repetitive and time consuming jobs, making them ideal for high-variability environments like e-commerce fulfillment centers. AMR is considered to represent the future of logistics, reducing setup costs and enabling rapid deployment in dynamic settings.

Key Features:

- Real-time environmental mapping and adaptability using AI and SLAM

- Seamless integration with WMS for automated picking and transporting

- Advanced obstacle avoidance with lidar and 3D vision for safe, efficient navigation

You can check Phenikaa-X’s AMR introduction site for more information about this autonomous robot.

4.2 Automated Guided Vehicles – AGV

Automated Guided Vehicles (AGV) are the workhorses of structured environments in automated warehouse equipment, designed for reliable, repetitive transport tasks along predefined paths. Operating on fixed routes guided by magnetic strips, embedded wires, laser navigation, or vision-based systems, AGVs ensure consistent performance in high-throughput settings. Their robust design supports heavy payloads, making them ideal for moving large pallets or raw materials in manufacturing and distribution facilities.

AGV often integrate with conveyor systems and warehouse control systems for synchronized operations, such as loading/unloading or staging inventory. In 2025, advancements in AI and sensor technology have enhanced AGV with limited autonomy, allowing them to handle minor deviations while maintaining their core strength: precision in repetitive, high-volume tasks. This makes AGVs a staple in warehouse logistics AGV applications where stability and predictability are paramount.

Key Features:

- High payload capacity for heavy loads, up to several tons

- Efficient navigation along fixed routes for repetitive tasks

- Compatibility with conveyor systems and WCS for seamless pallet handling

4.3 Articulated Robotic Arms

Articulated Robotic Arms, often referred to as automated arms, are precision-driven systems that bring human-like dexterity to robotic warehouse automation. Featuring multiple joints, these arms replicate complex movements for tasks requiring accuracy, such as picking, packing, and assembly. Equipped with advanced grippers, suction cups, or vacuum systems, they handle a wide range of items, from delicate electronics to bulky packages.

There are 02 types of Automated arms: one is fixed to a base and the mobile type that is mounted on movable platforms. The fixed type are quite traditional that work perfectly well in assembly line, while the mobile type are more modern and flexible, allowing them to move around the warehouse and do different tasks like sorting products or arranging them on shelves.

Key Features:

- Multi-axis design with advanced grippers for precise handling

- AI-powered vision systems for object detection and orientation

- High-speed operations for picking, packing and assembly tasks

4.4 Collaborative Robots

Collaborative Robots (Cobots) are designed for seamless human-robot interaction in robotics in warehouses, operating safely alongside workers without the need for protective barriers. Built with lightweight materials and force-limiting sensors, cobots prioritize safety, stopping instantly upon detecting unexpected contact. Their user-friendly interfaces allow non-experts to program tasks via intuitive software or manual guidance, making them highly accessible for small and medium-sized enterprises.

Cobots handle repetitive or physically demanding tasks like sorting, packing and inspection, complementing human workers in hybrid environments.Their flexibility and ease of deployment make them a key player in warehouse automation robotics, bridging the gap between manual and fully automated workflows.

Key Features:

- Force-limiting sensors and lightweight design for safe human collaboration

- Intuitive programming for quick setup and task flexibility

- Adaptability for repetitive tasks requiring human oversight

4.5 Automated Storage and Retrieval Systems

Automated Storage and Retrieval Systems (AS/RS) are high-efficiency solutions for maximizing storage density in automated warehousing. These systems use automated cranes, shuttles, or robotic arms to store and retrieve items from high-density racks, often reaching dozens of meters in height.

Controlled by sophisticated warehouse execution systems, AS/RS optimize vertical space, reducing the warehouse footprint while accelerating inventory access. They excel in environments with high inventory turnover, integrating with sorting and conveyor systems for streamlined order fulfillment.

In recent years, new models of AS/RS leverage IoT and AI for predictive inventory management, anticipating demand and minimizing retrieval times. Their ability to handle large volumes with precision makes them indispensable in robot storage for large-scale operations.

Key Features:

- Vertical space optimization with automated cranes and shuttles

- Fast access times through integration with WES and sorting systems

- High-density storage for large inventory volumes

4.6 Other Emerging and Specialized Types

Beyond the core categories, emerging warehouse robots are pushing boundaries in warehouse robotics solutions. These systems address niche needs and incorporate cutting-edge technologies to enhance flexibility and efficiency.

- Drones/Aerial Robots: A model of drone equipped with cameras and RFID scanners are being tested in the warehousing field. With their flying capabilities, these robots can scan cargo and products in packed areas that normal vehicles and humans found difficult to access.

- Sorting and Conveyor Robots: Designed for high-speed order processing, these robots automate sorting and transport in fulfillment robots for e-commerce. They integrate with conveyor belts and use AI to categorize items by size, weight, or destination, streamlining last-mile preparation. Their role is critical in high-throughput environments.

There are still many other types of robots working in warehouses that we are not listed here. They were made for niche and specific use (Cleaning bot for cleaning, Security bot for patrolling, Pickingbot for picking and sorting,…). The list of top 05 above are most common and can be used for multiple purposes, which make them become generic to be installed on most warehouses.

5. Future of Robotics in Warehousing

The future of warehouse robotics is poised for rapid growth, driven by advancements in complementary technologies that enhance efficiency, accessibility, and sustainability in logistics automation robotics. As warehouses evolve to meet rising e-commerce demands, warehouse robots will become smarter and more affordable, transforming logistics worldwide.

In recent years, automation technology has seen rapid advancements on a global scale, significantly benefiting the adoption of warehouse robots:

- Lower Costs: Cutting-edge technologies, such as SLAM and auto-mapping, have become standard features in autonomous robots, drastically reducing the cost of robots equipped with these. This affordability allows small and medium-sized enterprises to access logistics automation robotics more easily.

- Smarter Robots: Breakthroughs in AI and IoT have made these technologies more advanced and widespread in modern robots, with AMRs as a prime example. Warehouse robots can now operate more efficiently, rely less on human operators, and fully replace humans in simple tasks.

Current market conditions, with rising labor costs, are pushing business owners toward automation, which is increasingly seen as a cost-effective solution. However, this does not mean robots in warehouses will completely replace humans in the near future. Instead, they serve as powerful tools to optimize operations and drive business growth.

6. Some FAQs About Warehouse Robotics

To help warehouse managers and businesses better understand warehouse robotics solutions, Phenikaa-X addresses some common questions about implementing and using warehouse robots in modern logistics.

6.1 What Is the Cost of Implementing Warehouse Robots?

The cost of warehouse robots varies based on type and scale. For example, AMR and Cobot can range from $20,000 to $100,000 per unit, while AS/RS systems may require more for large-scale setups.

About cost of AMR implementation, the AMR price guide can help you further understand the cost of automation installed in the warehouse.

6.2 How Long Does It Take to Integrate Warehouse Robots?

Integration time depends on the robot type and warehouse complexity. Simple setups, like cobots, can be deployed in weeks, while complex systems like AS/RS and AGV may take months since they require infrastructure remodeling. Modern warehouse robots, such as Phenikaa-X AMR, can be quickly adopted and used immediately upon purchase with minimum change into your warehouse system.

6.3 Are Warehouse Robots Safe for Human Workers?

Yes, robots in warehouses prioritize safety. Equipped with advanced sensors like SLAM and LiDAR, robots like AMR and cobots detect obstacles, including humans, and adjust routes to avoid collisions, reducing workplace injuries.

6.4 Can Small Businesses Afford Warehouse Robotics?

Absolutely. While large-scale systems like AS/RS suit big operations, smaller businesses can adopt affordable options like cobots or single AMR. Their modular designs and low maintenance costs make warehouse automation robotics viable for, with scalable solutions to match growing needs.

Also, you can adopt these systems on a smaller scale, fewer in number as long as it suits your business needs.

6.5 How Do Warehouse Robots Handle Dynamic Environments?

Each type of robot has their own way to handle a warehouse environment, even if it’s complicated. For example AMR can use SLAM and LiDAR to create infrastructure maps, then pick up the most efficient route while automatically dodging obstacles. AGV and AS/RS need reflection duct tape and signs to guide them through different warehouse sectors, which means you will need to create a dedicated route for them.

Conclusion

This article provides an overview of Warehouse Robots, shared by engineers at Phenikaa-X. It’s clear that automated robot technology in warehouses plays a crucial role not only in business operations but also in financial benefits. The shift to automated warehouses is inevitable, bringing safer, more efficient work environments for workers and businesses alike.

Phenikaa-X is a leading pioneer enterprise providing automation technology solutions in Vietnam for industries such as manufacturing, services, healthcare and many more. Bring automation technology to your business and elevate it today by contacting us at:

- Facebook: https://www.facebook.com/phenikaa.x

- Hotline: (+84) 904530545

- Email: contact@phenikaa-x.com