Understanding the autonomous mobile robot price is crucial for businesses planning to invest in this technology. Prices vary widely based on robot type, features and implementation requirements, making it essential to evaluate costs carefully. In this guide, Phenikaa-X will provide you the cost of AMR implimentation, the factors influencing costs, as well as a comparison chart of each AMR type’s price.

1. What Are the AMR – Autonomous Mobile Robots?

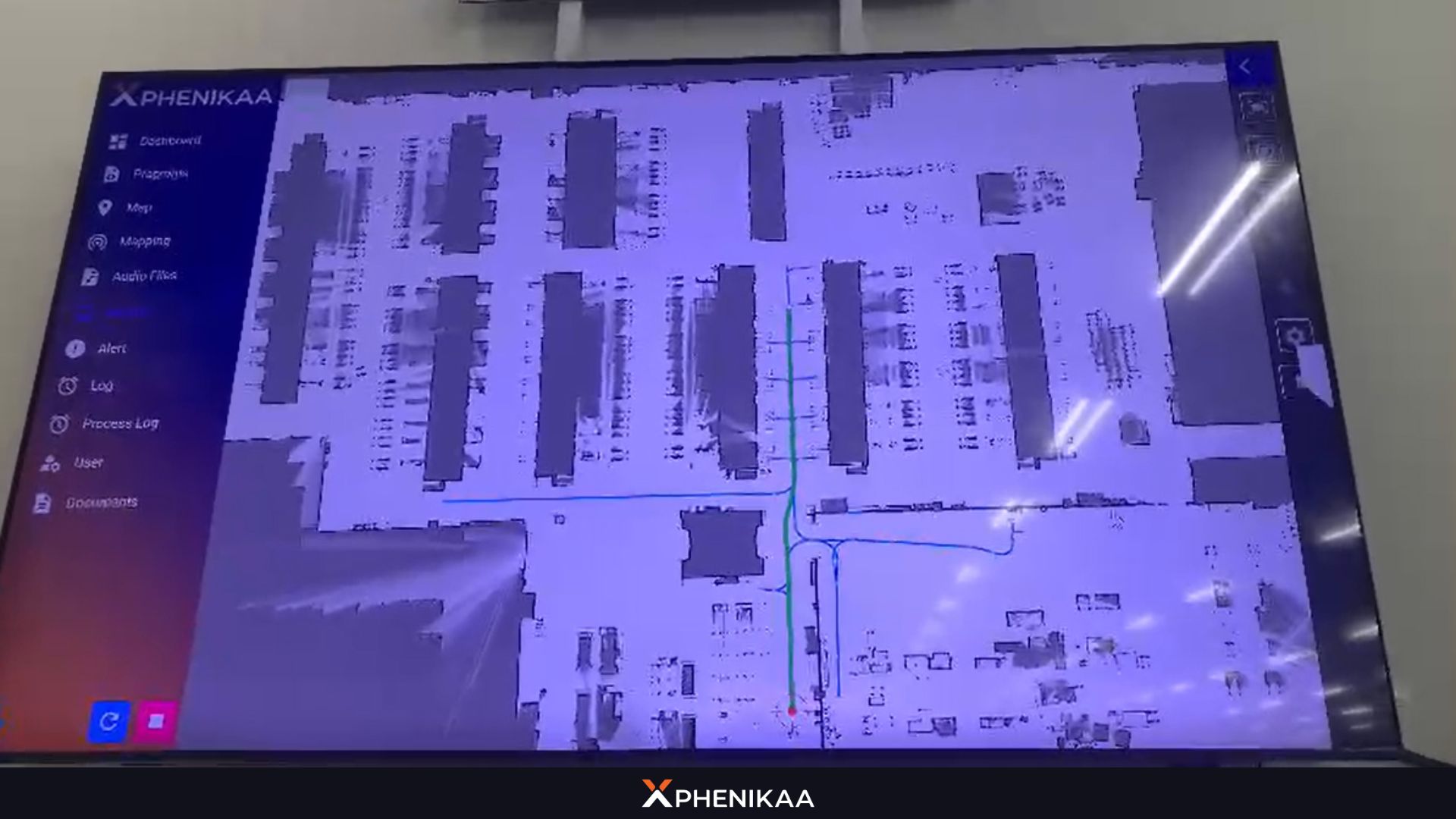

Autonomous Mobile Robots – AMR are self-navigating robots that move materials without fixed paths or human intervention. Unlike AGV (Automated Guided Vehicles), which rely on magnetic tapes or predefined tracks, AMR uses advanced technologies like LiDAR, SLAM, and AI to navigate dynamically. This flexibility makes them ideal for dynamic environments like warehouses, factories, and hospitals.

Their usefulness bring fresh air to the traditional manufacturing and warehousing businesses, for example:

- Transporting goods in warehouses autonomously.

- Supporting workers in manufacturing assembly lines.

- Delivering supplies in healthcare facilities.

- Streamlining order fulfillment in e-commerce.

Understanding these features helps you assess the AMR cost and choose the right solution.

2. Costs of Building an AMR System

Investing in Autonomous Mobile Robots requires careful planning to account for various costs beyond just the autonomous mobile robot price itself. These expenses encompass infrastructure, software, hardware and ongoing maintenance. Below, Phenikaa-X’s engineers list out the main costs to help you budget effectively for an AMR system.

Note: The cost listed here might different between countries. All prices are converted to US dollars for easy evaluation.

2.1. Installation cost

Installation costs cover the expenses needed to integrate AMR technology into your facility. These costs depend on the scale of your operation, the condition of your existing infrastructure, and any new installations required.

To make things easier to track, we will provide a detailed breakdown of each cost category, including its purpose to clarify what these expenses achieve.

- Infrastructure Costs ($5,000 – $20,000): The purpose of this investment is to create an environment that facilitates the operation of AMR, ensuring stable connectivity for real-time coordination and safe navigation without physical barriers.This included:

- Upgrading Wi-Fi for reliable robot communication and navigation.

- Optimizing warehouse layout.

Eventhrough AMR does not require specific adjustments to make them work like AGV, some change still needs to be made so that the AMR fleet can work efficiently with minimum risk of error.

- Software Installation Costs ($10,000 – $50,000): Fleet management software to coordinate multiple robots and optimize task allocation. Some common software included Warehouse Management Systems (WMS) or Manufacturing Execution Systems (MES) for seamless operations.

- Fleet management software to coordinate multiple robots.

- Integration with WMS/MES for seamless operations.

- Navigation mapping (using SLAM or LiDAR).

Normally the software is provided for free by the manufacturer. But to maximize the efficiency and create compatibility between AMRs from different manufacturers, investment on 3rd-party software will be the better option.

- Installation and Deployment Costs ($5,000 – $15,000): These costs ensure the AMR system is tailored to your facility’s layout, fully operational, and tested to minimize errors and maximize efficiency from day one.

- Mapping the facility, configuring robots and testing the system.

- Often provided by the supplier but varies by project complexity.

- Training Costs (Free – $10,000): Training staff to operate, monitor, and manage the AMR system. Often includes on-site training sessions provided by the supplier. The cost for this is fully dependent on the manufacturer or business size of the facility and other requirements.

- Maintenance and Upgrade Costs: Maintenance keeps AMR running reliably, while upgrades allow the system to adapt to new requirements, extending its lifespan and functionality. Depending on the condition of the facility, the workload of the AMRs, maintenance cost might be different each year.

2.2. Autonomous Mobile Robot price for each types

There are different AMR types, each designed for specific tasks and industries. With different types of AMR and different add-on installed on them, the cost of AMR fleet is not the same for all factories. Here are the AMR prices Phenikaa-X researchers collected, based on industry data from sources on the market and manufacturer’s websites.

- AMR Platform (Mobile Platform): A Low-profile AMR model with a flat surface, can support 100-500 kg payloads. This model is mainly used on transport racks or carts, integrated in warehouses and internal logistics in factories.

Average Price: $25,000 – $40,000 per unit.

- Autonomous Forklift: Traditional forklift design with automated lifting, handling 500-2000 kg. Used for Lifting pallets, navigates autonomously, and syncs with WMS for efficient warehouse stacking.

Average Price: $60,000 – $100,000 per unit.

- Mobile Picking Robot: Compact robots with robotic arms or picking systems, designed for small payloads, which make them suitable for working on E-commerce and smart warehouses.

Average Price: $50,000 – $60,000 per unit.

- Autonomous Tow Tractor: Equipped with a towing system, this type of AMR can pull multiple carts and handle large payloads. Due to the size, they mostly support outdoor navigation in large factories, airports and ports.

Average Price: $30,000 – $50,000 per unit.

- Collaborative AMR: Small, agile robots with 50-200 kg capacity, designed for human-robot collaboration. Best suit for small-scale facility,

Average Price: $20,000 – $35,000 per unit.

- Heavy-Duty AMR: Robust robots for payloads over 500 kg, up to 2 tons. They can easily handle heavy materials like car engines and metalwork, making them best suited in Automotive and aerospace manufacturing.

Average Price: $80,000 – $150,000 per unit.

| AMR Type | Payload | Applications | Price Range |

| AMR Platform | 100-500 kg | Warehouses, factories | $25,000 – $40,000 |

| Autonomous Forklift | 500-2000 kg | Logistics, warehousing | $60,000 – $100,000 |

| Mobile Picking Robot | Small payloads | E-commerce, smart warehouses | $50,000 – $60,000 |

| Autonomous Tow Tractor | Large payloads | Factories, airports, ports | $30,000 – $50,000 |

| Collaborative AMR | 50-200 kg | Flexible manufacturing, small warehouses | $20,000 – $35,000 |

| Heavy-Duty AMR | >500 kg | Automotive, aerospace | $80,000 – $150,000 |

3. Factors Affecting AMR Prices

There are also some factors that might cause autonomous mobile robot prices to become significantly cheaper or more expensive. To make sure that you can spend your budget effectively and avoid overpaying, here are some important factors that need to put in mind:

- Payload and Size: Robots with higher payload capacities or specialized sizes cost more due to advanced engineering. But in trade with that, working effectiveness might be increased.

- Navigation Technology: Advanced systems like LiDAR or AI-driven SLAM are more modern and costly. Robots with such technologies will perform better, making it worth the investment.

- Additional Features: IoT integration, fleet management software, or outdoor capabilities add to the cost. This feature is optional, depending on the manufacturers, so you need to check if your ARM includes them or not.

- Brand: Of course, each brand have their own price for each type of AMR. You should check the prices labeled on the website, or contact customer service for detail and have a comparison before investing in the technology.

- Implementation and Maintenance: Costs for installation, training, and ongoing maintenance can significantly impact the total investment.

- Customization: Tailored AMRs for specific industries (e.g., healthcare or retail) are pricier due to bespoke design. Also, any add-on feature on the standard model will be more costly for each unit.

You should also check the Top 10 Best AMR Manufacturers. This guide was made by Phenikaa-X’s market researcher by doing research on pricing listed on the manufacturer websites and their catalogues, so that you can easily understand which brands are the most suit for your business.

4. Is AMR Worth Investing In Compared to Other Automation Solutions?

When considering the autonomous mobile robot price, it’s essential to compare AMR with other automation solutions like Automated Guided Vehicles (AGV), conveyor systems, and of course, with the good-old traditional manual labor too. Below is a detailed comparison based on cost, infrastructure requirements, tasks and more.

| Criteria | AMR | AGV | Conveyor System | Manual Labor |

| Average Cost | $20,000 – $150,000/unit | $15,000 – $80,000/unit | $100,000 – $500,000/system | $20,000 – $50,000/year/worker |

| Infrastructure Modifications | Minimal (Wi-Fi, navigation maps) | High (magnetic tapes, fixed paths) | Very high (fixed installation) | None |

| Tasks Addressed | Flexible transport, picking, human collaboration | Fixed-route transport | Bulk transport, assembly lines | Varied, skill-dependent |

| Flexibility | High (reconfigurable, scalable) | Low (fixed routes) | Very low (fixed system) | High, but less efficient |

| Maintenance Costs | Moderate (software, sensors) | Low (simple technology) | High (mechanical parts) | None (training costs apply) |

- AMR: Higher initial costs than AGVs but offer unmatched flexibility and minimal infrastructure changes, ideal for dynamic warehouses or e-commerce.

- AGV: Cheaper but requires costly infrastructure like tracks, limiting adaptability.

- Conveyor Systems: Best for high-volume production but expensive and inflexible, requiring significant facility modifications.

- Manual Labor: Low upfront cost but inefficient long-term, with risks of errors and rising labor costs.

For detail comparisons between AMR vs AGV, Phenikaa-X’s engineer made an detail article that you can easily check anytime.

AMRs are a worthwhile investment for businesses prioritizing flexibility, scalability, and long-term cost savings, especially in logistics and e-commerce. Their ability to operate without major infrastructure changes makes them a cost-effective choice compared to AGV or conveyors.

To fully understand which kind of AMR you need, you should also learn more about How Do Autonomous Mobile Robots Work, shared by Phenikaa-X engineer.

5. Some Tips to Optimize Your AMR Investment

To maximize the value of your AMR investment and manage the autonomous mobile robot price, there are some tips you might want to remember:

- Match AMR to Your Needs: Avoid overpaying for features you don’t need. For example, choose collaborative AMRs for small warehouses instead of heavy-duty models.

- Explore Robot as a Service (RaaS): RaaS models allow you to lease AMRs, reducing upfront costs and including maintenance.

- Evaluate Total Cost of Ownership (TCO): Factor in maintenance, upgrades and training to understand long-term expenses.

- Compare Multiple Suppliers: Request quotes from trusted providers to find competitive pricing. Learning from another factory or warehouse that is already invested in AMR should also be a great idea.

By following these strategies, you can reduce costs while ensuring your AMR system delivers maximum efficiency. You can also learn about some of the AMR Implementation Case Studies in China to understand how AMR can improve your business, as well as their insight.

Conclusion

With autonomous mobile robot prices ranging from $20,000 to $150,000 per unit and total system costs between $100,000 and $500,000, AMR are a significant but worthwhile investment. Their ability to operate without major infrastructure changes, coupled with long-term savings, makes them ideal for businesses seeking efficiency.

Phenikaa-X is one of the best AMR and robotic solutions providers. Contact us today to learn more about integrating AMRs into your business:

- Facebook: https://www.facebook.com/phenikaa.x

- Hotline: (+84) 904530545

- Email: contact@phenikaa-x.com