Did you ever wonder how engineers can control the autonomous vehicle, or so called AGV, in industrial and manufacturing? The secret lies in advanced software allowing humans to give command to these robots. Together with Phenikaa-X in this article and dives deep into the world of AGV, answering the question, “What is AGV Software?”

1. What is AGV Software?

AGV software, also know as AGV app, is the application systems built to control, manage and optimize AGV – automated guided vehicles work. Basically, AGV software is the core of interaction between humans and the Robot, ensures these vehicles can perform tasks like moving goods, avoiding obstacles, and coordinating with other systems seamlessly, allowing humans an easy way to interact with these robots.

Functionally, AGV software is a combination of navigation tools, fleet management capabilities and integration features that allow operators to interact with AGV. This software takes data from sensors, processes it in real time and updates all that information to the operator. From that, the operator can easily know if the fleet is working at maximum efficiency, correct the error ASAP and ensure that the job-well-done from the AGV robots fleet.

Over the years, AGV app has evolved from basic path-following programs to advanced, AI-driven platforms capable of handling complex logistics challenges. Today, it’s an essential component of modern automation, bridging the gap between hardware and operational efficiency.

2. How Does AGV Software Work?

AGV software enables the seamless operation and management of Automated Guided Vehicles through a structured process. Here is how it works in simple steps:

- Installing the Application on Suitable Devices

The software is first installed on compatible devices, which may include smartphones, tablets or computers. Depending on the system, it can support various platforms such as Android, iOS, Windows, or other operating systems. This flexibility allows users to access the software from devices that best suit their operational needs and not restricting the users into any specific platform.

- Connecting the Application to the AGV Robot

Once installed, the software establishes a connection with the AGV robot. This is typically done via wireless communication methods like Wi-Fi, Bluetooth, or industrial protocols, depending on the AGV’s hardware and the facility’s network setup. The connection links the software to the AGV’s onboard control unit, enabling two-way communication.

For example, Phenikaa-X’s AGV app can be easily connected via Wi-Fi network. This allows the installation of the AGV to become far much easier compared to other connect methods, also increasing the convenience, since Wi-Fi and internet connection is now an essential part of any industrial field.

- User Interaction with the Robot via a Control Panel

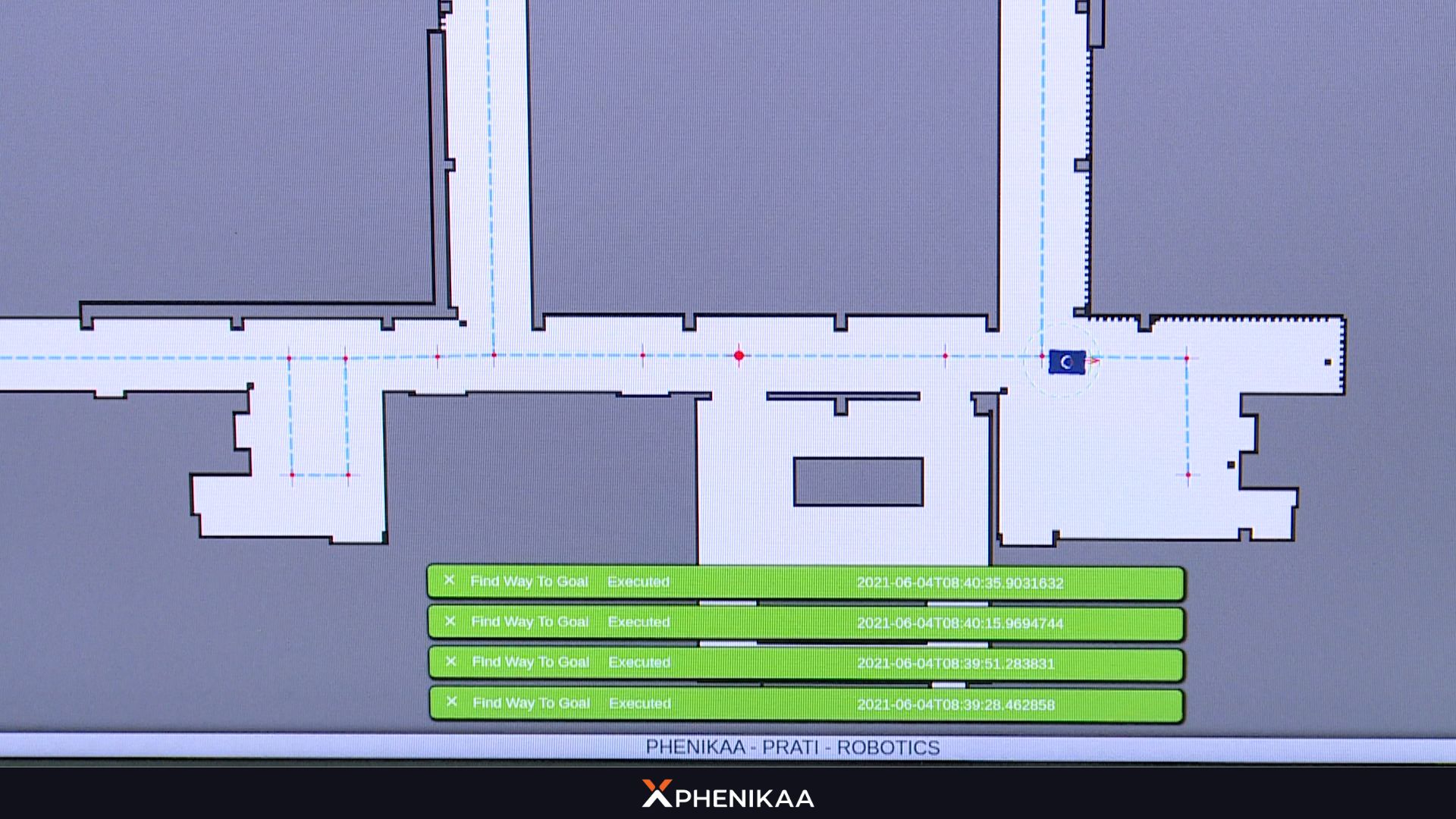

Users interact with the AGV through a user-friendly control panel or interface provided by the software. This dashboard allows operators to input commands, set tasks and monitor the robot’s status. The interface is designed to simplify complex operations, making it accessible even to non-technical users.

- Robot Receiving and Executing Commands Based on User Requests

After receiving commands from the control panel, the AGV’s onboard system processes them and executes the required actions. For example, if instructed to transport a load, the AGV uses its navigation system to follow a path and complete the task. The software ensures that these instructions align with the robot’s capabilities and the environment it operates in.

- Real-Time Operational Data Sent Back to the Management Software

As the AGV robot performs its tasks, it continuously sends operational data back to the software in real time. This data includes details like the robot’s location, battery level, task progress and errors occurred. The software collects and displays this information, allowing users to monitor performance, troubleshoot issues, and optimize operations on the fly.

In summary, AGV software works by bridging the gap between human operators and robotic systems. Through installation, connection, user control, command execution, and real-time data feedback, it ensures that AGVs operate efficiently and remain fully integrated into the workflow. This process enhances automation, improves productivity, and provides operators with full visibility into AGV activities.

3. What can AGV software do?

From how it works written above, it is easy to realize that AGV app operates as the central nervous system of the AGV fleet, orchestrating its every move. In general, the AGV monitoring software system operates around the following activities:

- Receives and delivers tasks: Operators manually give tasks for the AGV fleet through AGV software in order of importances, for example – transporting a pallet from point A to point B. After receiving an order, AGV will check the task that needs to be prioritized, then use its navigation systems to chart the best route.

- Fleet management: In facilities with multiple AGVs, the software coordinates their movements to prevent collisions and optimize traffic flow. Operators can assign priorities, schedule tasks, and ensure each AGV robot operates at peak efficiency.

- Integrates with other systems: AGV app also enables syncing with broader systems, like warehouse management software (WMS), enterprise resource planning (ERP), or manufacturing execution systems (MES). This connectivity allows it to align AGV operations with production schedules or inventory needs.

- Analytics: Detailed reports on performance, downtime, and efficiency help businesses refine their processes.

With the advance of IoT technology, now AGV can picture their roadmap in the factory and send it back to the software. The roadmap can show all the travelling path, the task AGV is enlisted on,… all can be checked easily and guided by intelligent software.

4. Benefits of AGV Software

Why choose AGV software? Its standout advantages make a strong case:

- Efficiency: Some AGV software is designed to be user-friendly and accessible for workers, even if it’s not supplied by the AGV’s original manufacturer. This simplifies factory operations and cuts down on training costs, as employees can quickly learn to use it without extensive preparation.

- Flexibility: Developers have made AGV app compatible with a wide range of devices and platforms. Now, operators can control AGVs conveniently from smartphones, tablets, or other tools, no matter where they are, enhancing operational ease.

- Safety: Certain AGV application includes advanced safety features integrated into the control system, such as emergency stop buttons. This allows operators to instantly identify issues and intervene in real time, reducing risks and boosting workplace security.

5. Challenges and Limitations of AGV Software

While AGV software offers significant benefits, it faces notable challenges:

- Learning Curve: One major issue with automation technologies, including AGVs, is the difficulty of mastering them in a short time. The complexity of the software can overwhelm users, requiring extensive training to operate effectively.

- Compatibility Issues: The software’s compatibility with AGVs from different manufacturers poses another hurdle. Variations in hardware and protocols can lead to integration difficulties, making it tricky to ensure seamless operation across diverse systems.

However, as technology advances daily, temporary solutions are emerging, reinforcing AGV systems and their software as the future of industrial automation:

- Simplified User Interface: Modern AGV app now features easier-to-understand UIs, streamlining interaction for operators and reducing the learning barrier.

- Improved Software Synchronization: Software is becoming easier to sync across platforms and AGV models, enhancing interoperability. That said, it’s still crucial to verify compatibility with providers before investing in either the AGV robot or its software to avoid potential mismatches.

These advancements are making AGV app more accessible and adaptable, paving the way for broader adoption despite its challenges.

6. The Future of AGV Software

What’s next for AGV software? Engineers around the world are trying their best to improve user experience and add more advanced technology to the control system. Recently, there are some tech are being experimented with, such as:

- AI and Machine Learning: Future software will predict obstacles, learn from past tasks, and optimize operations autonomously.

- 5G Integration: Faster networks will enable real-time control and communication, even across large facilities.

- Cloud-Based Systems: Remote management and scalability will become standard, reducing on-site infrastructure needs.

- Sustainability Focus: Energy-efficient algorithms will align AGV operations with green goals.

The goal of these attempts are to make the system smarter, easier to connect with any AGV from any provider, and to make automated technology become easier to access in any field of industry.

6. How to Choose the Right AGV Software

Selecting AGV software requires careful consideration:

- Assess Needs: Identify your industry’s demands-warehousing might prioritize speed, while manufacturing needs precision.

- Compatibility: Ensure the software integrates with your existing WMS, ERP, or MES.

- Vendor Reputation: Choose providers with proven track records and robust support.

- Scalability and Support: Pick a solution that grows with your business and offers reliable customer service.

- Trial and Testing: Run pilot programs to confirm the software meets your goals.

7. FAQs

- What is AGV software used for?

AGV software controls automated guided vehicles, enabling them to transport materials, navigate spaces, and coordinate tasks efficiently.

- How does AGV software differ from traditional automation systems?

Unlike static automation, AGV software offers dynamic navigation and fleet management, adapting to real-time changes.

- Can AGV software work with older AGV models?

Yes, with updates or retrofitting, many older AGVs can integrate modern software, though compatibility varies.

- What industries benefit most from AGV app?

Logistics, manufacturing, healthcare, and e-commerce see the greatest gains from AGV software’s efficiency and flexibility.

- How much does AGV application typically cost?

Costs vary widely, depending on fleet size, customization, and integration needs.

Conclusion

AGV software is more than just an application or some code. It is the powerhouse behind the automation revolution, driving efficiency, safety, and innovation across industries. From navigating bustling warehouses to streamlining factory floors, Phenikaa-X gives you the answer for the question, “What is AGV Software?” with a resounding impact. As technology advances, its role will only grow, making now the perfect time to explore its potential.

Phenikaa-X is one of the best AGV and robotic solutions providers in the Asia and we are now shipping worldwide. Contact us today to learn more about integrating AGVs into your business:

- Facebook: https://www.facebook.com/phenikaa.x

- Hotline: (+84) 904530545

- Email: contact@phenikaa-x.com